Busbar Punching and Bending

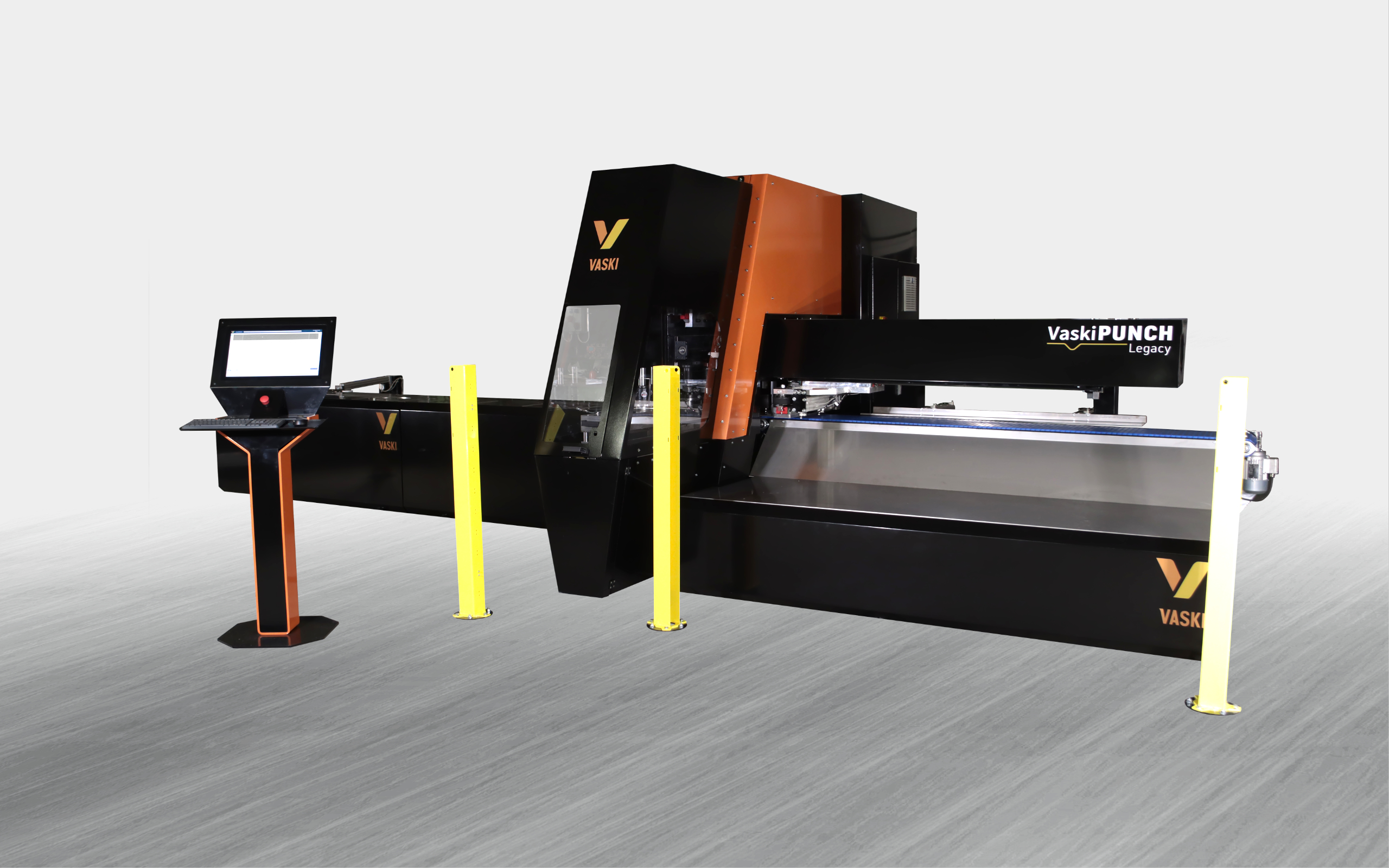

VaskiPUNCH

VaskiPUNCH is a machine for flat bar punching and cutting, and it is most of the times used for processing busbars. Unlike others, it is servo-electric, which enables exceptional 80% savings on energy consumption and CO2 emissions, when comparing to hydraulic powered.

Tooling system on the VaskiPUNCH is extremely flexible as most of the existing tools can be mounted, and that makes it the most versatile punching machine on the market. The machine accommodates Thick Turret, extended Thick Turret and multiple styles in the magazine at the same time. The tooling magazine can accommodate two B-stations in one D-station, all together 1 cutting tool + 10 B-stations.

The operator uses a 20” touch screen, which is very user-friendly for part programming, or selecting the program made in the office. Not only it is the fastest punching machine on the market, but also it lacks the continuous noise pollution vs. hydraulic.

Fully servo-controlled by CNC axes

The VaskiPUNCH features progressive stroke control for high tonnage and high speed. Mechanically operated unloading system that automatically drops finished parts to a lower level for further processing for the operator. Optional device for further automation.

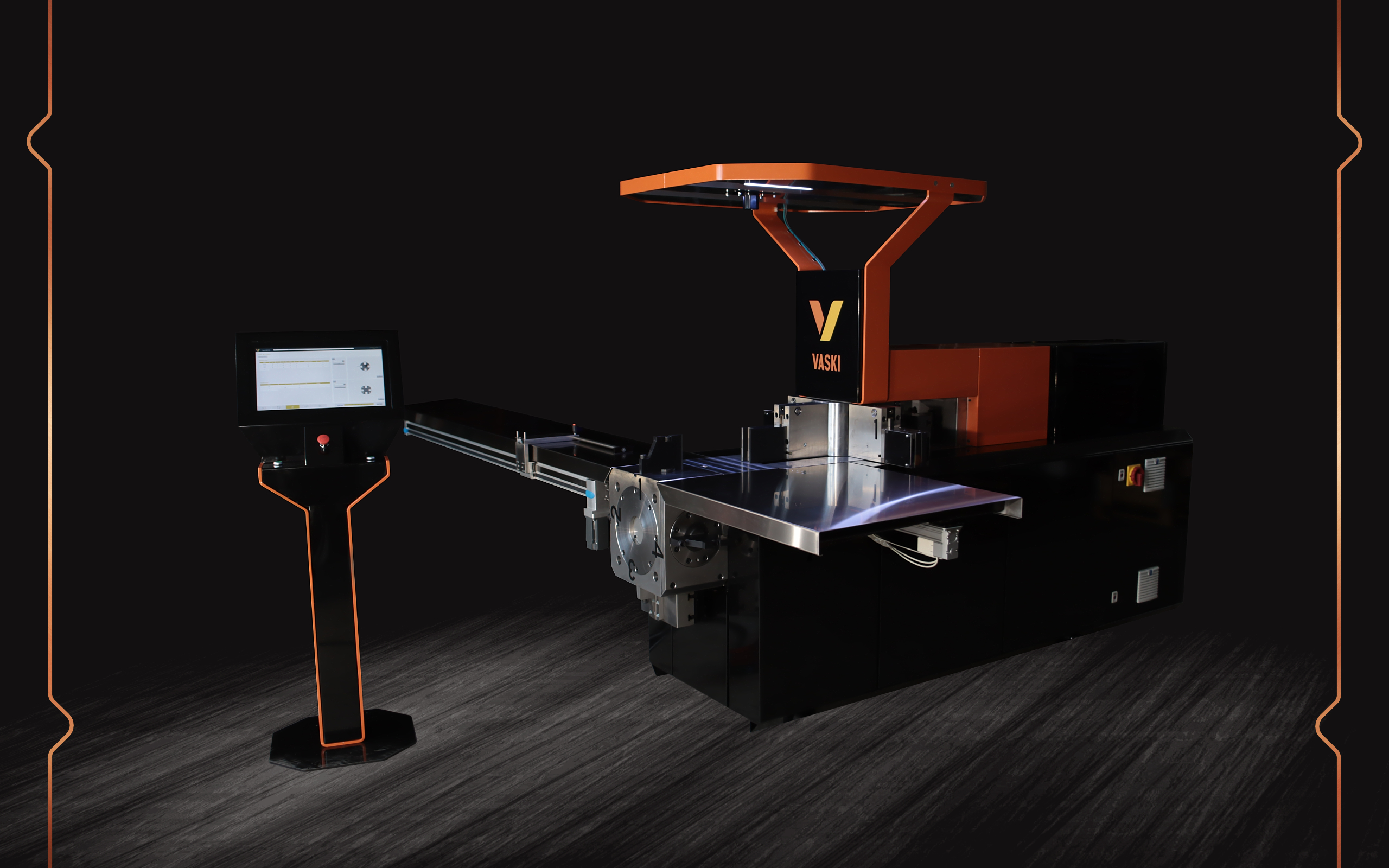

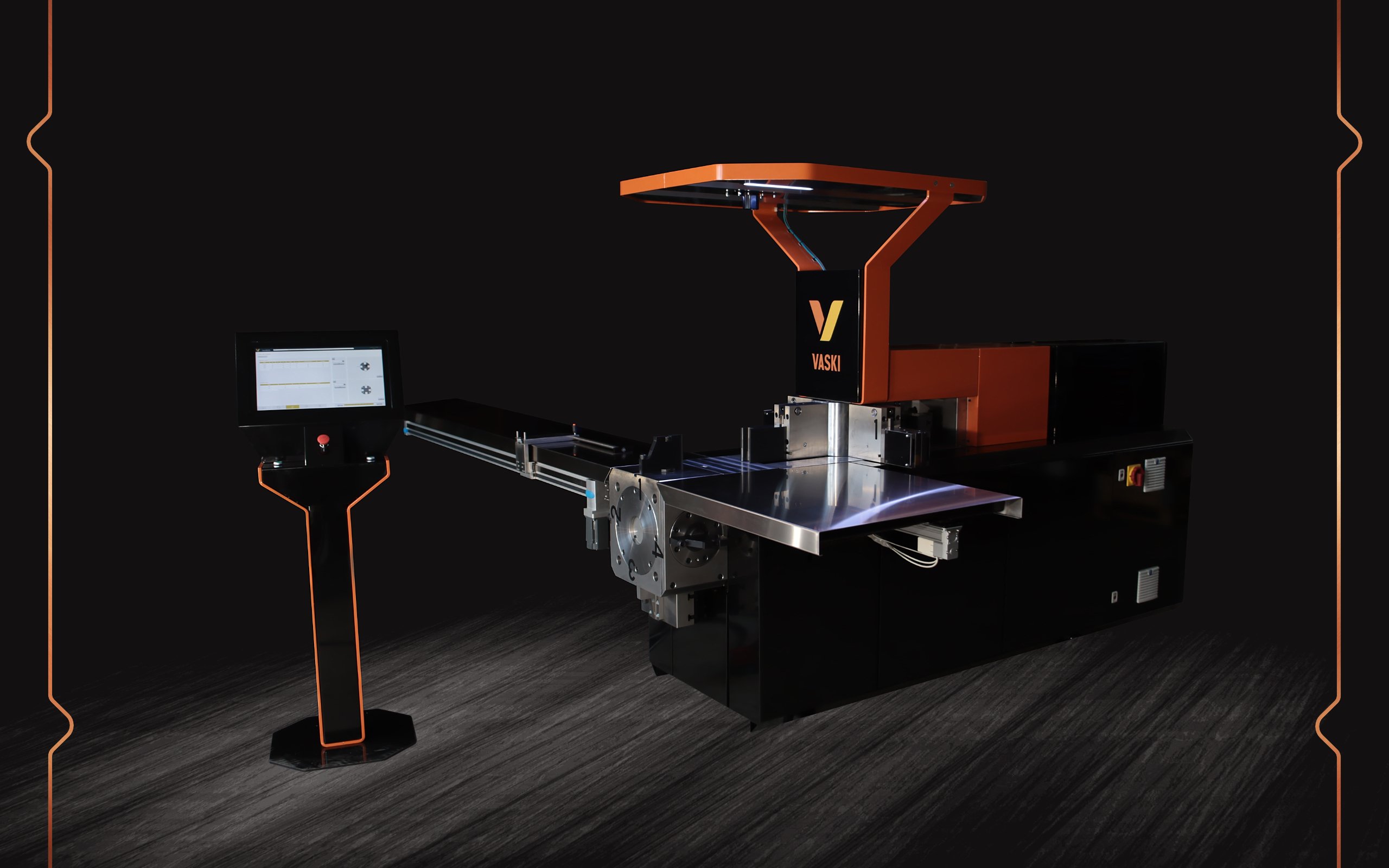

VaskiBEND

High Production Efficiency

The VaskiBEND is a versatile machine family which can bend flat bar components, accepting various flat bar widths from 15mm up to 200mm and thickness from 3mm to 20mm.

This machine family is built to be an energy efficient, high accuracy horizontal bending machine featuring servo-electric technology combined with a fast and accurate servo controlled back gauge. The technical solutions of the machine provide high production efficiency. The modular design concept allows a wide range of automation alternatives for meeting specific needs.