Magnetic Core Drilling Machine

Hytek provides different purpose Core drilling machines:

- Core drilling machine with electromagnets

- Core drilling machine with permanent magnets

- Core drilling machine with electromagnet and R/Barrel

- Core drill with a machine with permanent magnet and R/Barrel

- Core drilling machine with vacuum plate

Benefits of Core drilling equipment

- Time-saving.

- Energy savings.

- More finishing.

- Efficient cooling.

- Does not require very powerful machines.

- Sizes.

- Re-sharpening.

Applications of Core drilling tools

- In the construction industry, core drills are used for things like the creation of passageways

- Space for electrical wiring including phone and cable lines

- Concrete walls, floors, ceiling, location, and air conditioning systems, road cores, manholes, strength test holes

Hytek supplies electrical devices and tools for punching and drilling metal with a material thickness of 0.8 mm to over 100 mm. Application solutions from magnet and lifting technology are also part of our product world. We also offer special solutions for projects such as small series or prototypes.

Equipped with a permanent magnet or electromagnet, the models from the Alfra Rotabest ® family stick, depending on the model, from a material thickness of 3mm. We offer the perfect core drilling machine for every need. For horizontal drilling, applications in T-beams, in tight angles, or for thread cutting with RLE drive.

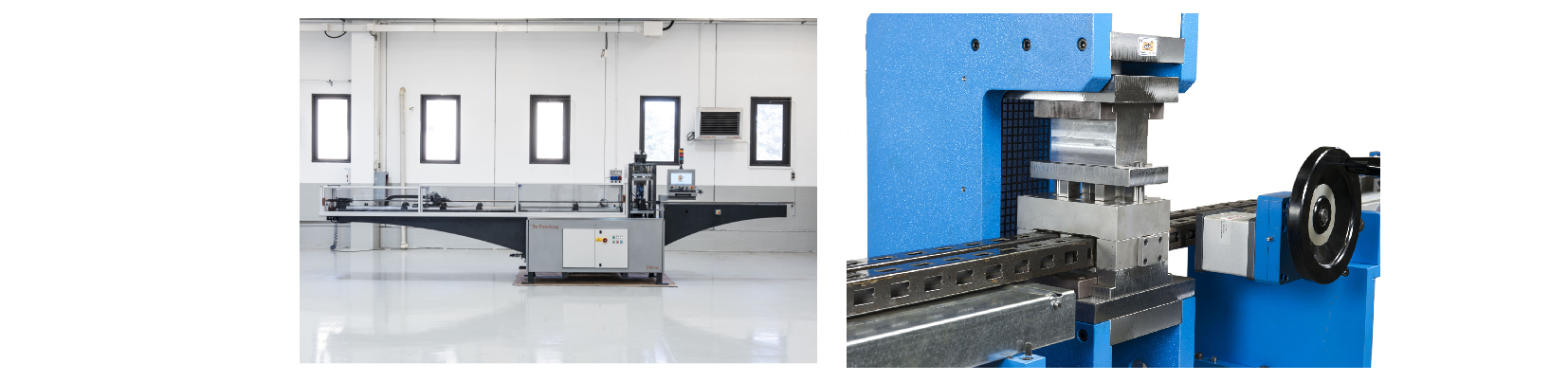

Core drilling machine-SP series

Our core drilling machines from the SP series are something special. Because they are not only reliable helpers on construction sites, in metal processing companies, or in shipyards - they also give you a piece of freedom. Like all models in the SP line, the RB 35 SP adheres to the material thanks to a permanent magnet - from a thickness of 3 mm and completely independent of the power supply. "Crashes" in the event of a power failure are thus excluded. The sensor function also ensures maximum occupational safety. The LED light indicates whether the material the machine is sticking to is strong enough. In addition, the magnetic base can be easily positioned thanks to the pre-tensioning.

Another plus: With a deadweight of only 9.9 kg, our 35 SP leaves the competition far behind. You receive quality "Made in Germany" in a particularly user-friendly form: the SP line combines all performance features for metalcore drilling with ergonomically perfect operating comfort and well-thought-out equipment. For example soft start and overload protection. Drill safely in any position with a cutting depth of up to 50.0 mm. The RB 35 SP works with core drills up to a diameter of 35 mm, with twist drills up to 13 mm, and with step drills with a diameter of up to 40 mm.

.jpg)