Plate Rolling Machine

HAEUSLER, Switzerland is not just a name, HAEUSLER is a conviction. Because our Plate Rolling machines not only help you reach your goals faster, they also stand for legendary quality. That is why it is our daily aspiration not only to meet the high demands of our customers, but to exceed them.

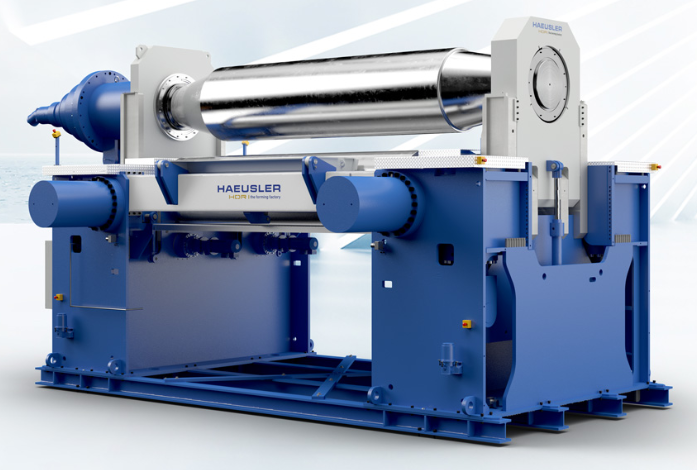

HDR 3-roll plate bending machine

First-class HAEUSLER quality and expertise paired with durability and low operating costs – this is exactly what you get with the 3-roll plate bending machine HDR from HAEUSLER. The HDR convinces by the individually adjustable bending geometry of the bottom rolls, which enables rolling of very thick plates as well as small diameters. Best bending results can be achieved thanks to the use of the patented top roll adjustment by using only pressure loaded cylinders and thus resulting machine symmetry.

The HAEUSLER HDR bending machine differs in many ways from other 3-roll bending machines on the market. For example, the symmetrical design of the HDR ensures accurate and optimal bending results. It is difficult to achieve a good bending result on machines with an asymmetrical design. Also, the four used and identical pressure cylinders of the HDR bending machine offer considerable advantages compared to outdated designs of competitors, such as highly accurate synchronisation.

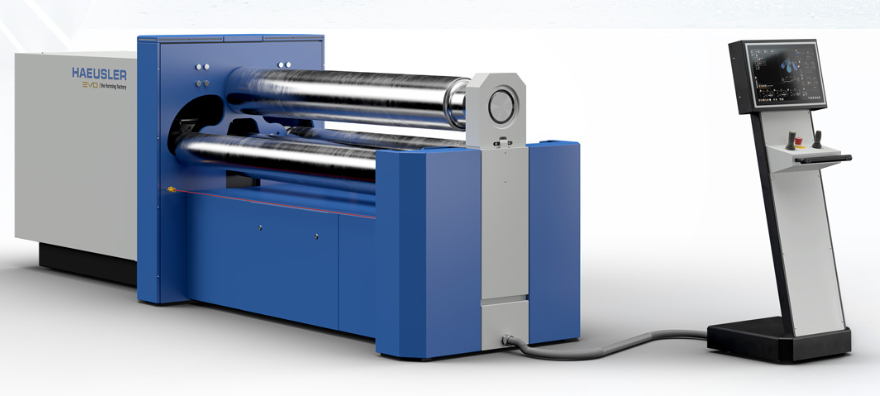

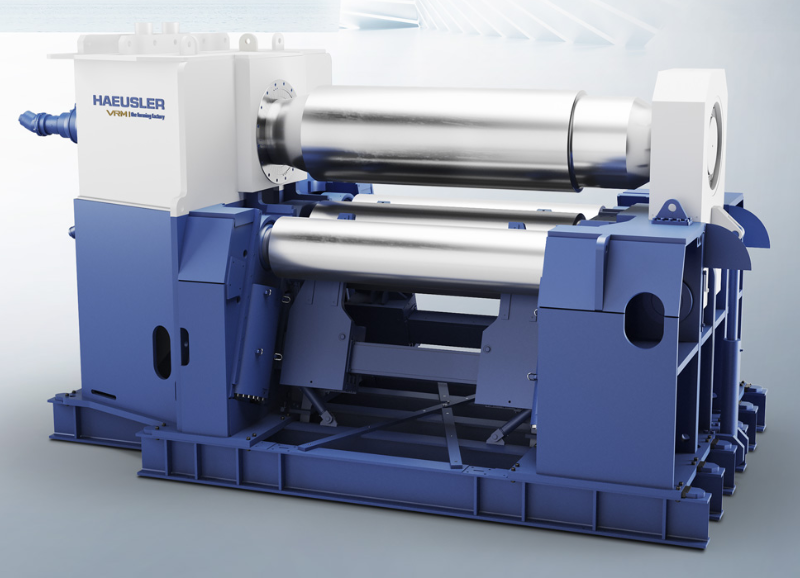

VRM NEO 4-roll bending machine

With the introduction of the VRM NEO, HAEUSLER AG, leading manufacturer of plate bending machines, is setting new standards in the metal bending industry. This 4-roll bending machine has been newly developed and integrates the latest technologies for a wide range of applications. Whether wind turbines in onshore or offshore operation, silo construction and mechanical engineering or container production – the VRM NEO masters the challenges of these industries like no other.

The VRM NEO sets new standards in bending technology by offering intelligent, flexible and energy-saving solutions for modern production lines. With the intelligent BENDtronic® control system, autonomous bending, an innovative electric drive and energy-saving hydraulics, the VRM NEO enables maximum efficiency and adaptability.

The high productivity of the VRM NEO results from the consistent implementation of the 4-roll concept with linear guidance of the side roll positioning infeed and fast electric rotary drive. With the 4-roller concept, the plate is always clamped between two rollers, which facilitates handling and automation and thus enables time and material-saving bending.

The extended linear guides allow for extreme roll diameters and make the machine extremely flexible for bending cones, complex shapes with multiple radii and narrow cylinders. The flexibility of the 4-roll concept in combination with the high rotation speed of 8 m/min make the VRM NEO the most productive plate bending machine.