All You Need To Know About Before Buying The Welding Fume Extractor

When we are doing welding works in metal welding fumes will generate, welding fume extractor is equipment that helps to remove these hazardous fumes. These fumes are carcinogenic and can have dangerous long-term effects if not correctly removed from the breathing zone.

What Exactly Is Welding Fume Extractor?

So it’s necessary to take precautions to remove these fumes as they affect the employees' health very severely.

Welding fume extraction systems and extraction units are capable of removing all kinds of smaller dust particles and welding fumes. And also they will improve indoor air quality and also work as protective equipment. A Welding Fume extractor acts as a protecting shield by capturing airborne particles and contaminants before their spread in the local environment.

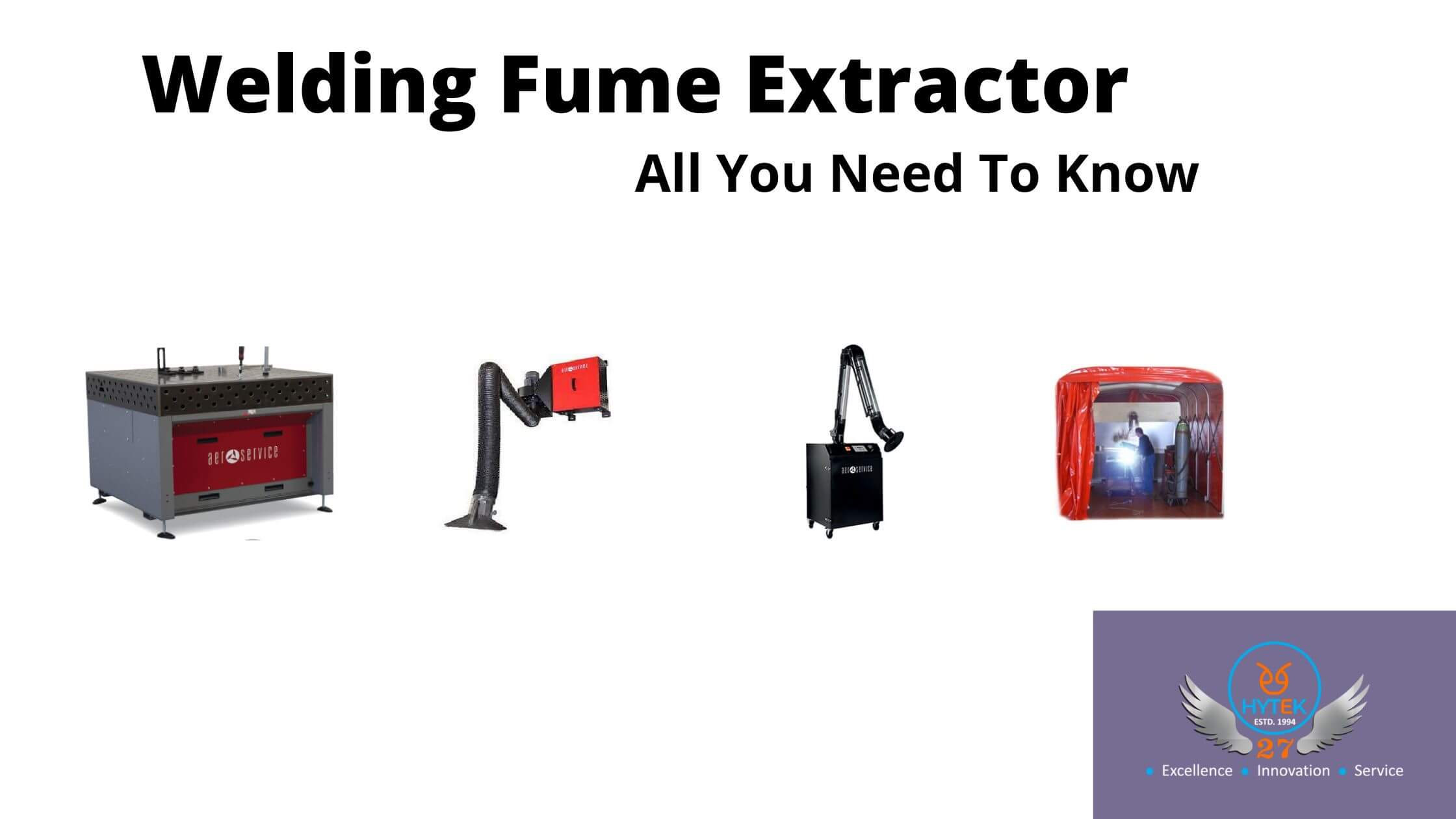

We have to choose Welding Fume extractors based on your requirement from light to moderate to intensive usage. Portable welding fume extractor, Mobile welding fume extractor, and Stationary welding fume extractor are some of the models in Welding Fume extractors, which you have to choose as per your requirement.

The Application of Welding Fume Extractor is Welding fume Filtration, Welding fume Killer system, Robotic Welding Fume Extraction & Dust Extraction, Soldering Pot Fume Filtration, Laser Fume Filtration, Hazardous Fume / Dust Filtration / Odor Removal, Medical Lab Gas / Fume / Dust Filtration, Pharma lab Dust Filtration, etc.

A negative draft of a fan is used to pull fumes and dust particles into a contained filtration system, this is how a fume extractor works. Processes including welding, sanding, grinding, spraying and processes involving exhaust fumes need this type of extraction to protect people, machinery, and of course the environment that we all share.

Best welding fume extractors will contain the below features

Extraction Power

We have to make sure the energy efficiency and Extraction power are adequate. Hazardous components are to be removed immediately from the workplace, channeled into the pipe system, and expelled, or suitably filtered to recirculate clean air.

The capacity of the welding fume extractor that we need will depend on how big is your facility or workshop. There should be an effective extraction at the source.

High Air Filtration Efficiency

While selecting a Welding fume extractor check for the best filtration options which has a high rate of suction airflow and purifying efficiency. Recirculating filtered air is a solution that avoids temperature dispersion and then reduces heating costs.

This is mainly recommended especially for repair shops that work in rigid climates. So it should be equipped with efficient filters, suited to the dust concentration that characterizes the fumes.

Less Maintenance and Durability

Easy operation and maintenance with low system costs. Hassle-free replacement and cleaning of filters.

User-Friendly

Make sure there is an Electronic panel board in the Welding Fume extractor you will buy. It should have a Functional mobile design and Flexibility facilitates easy movement. Convenience to operate is an unimportant factor to consider.

The extractor that is directly connected to the welding torch ensures that the extraction is always accessible and correctly positioned. Work becomes flexible with excellent capture. And also try to get a Welding Fume Extractor that has a low noise level, so that it won’t affect the peace in the working environment.

Meeting the regulations

Regulations set by various regulatory authorities are to be met, to reduce the risks of exposure to hazardous fumes. Welding fume extraction system manufacturers in India have a great scope in the market because of the growing population in India.

If we don't take care of these kinds of hazardous fumes, the chances of affecting a significant population are higher. Indian regulations are more supportive of the prevention of any risk caused by industries.

Customization according to specific needs

Each fume extractor must be installed in a system that can best adapt to the customer's needs. It is always recommended to buy self-cleaning versions of welding fume extractors available on the market; this will help to reduce maintenance costs and durability.

Spares and service

The sensors in each filter that the extraction units use will inform you when they need to be changed. Changing the filters is a process that typically needs to be done within a twelve-month time frame for the equipment to maintain its full capacity.

It is easy and simple to follow the instructions to change your dust and fume extractor filter. Check the availability of spare parts and services before confirming your Fume Extractor. You should make sure the spare parts are easily available and you should be able to avail of the service at any time without having trouble.

Feedbacks and Reviews

Make sure you have all information about the product and you have collected all feedback given for that product before buying Welding Fume Extractor. Don't forget to check the review, they will give you a better idea about the product and its working from the real customers, who already have used or are using that same product.

Conclusion On All You Need To Know About Before Buying The Welding Fume Extractor

So now you know the importance of selecting the best welding fume extractor. Please refer to these points before buying. Select the best one which is easy to use, cost-effective, durable, and effective.

The necessity of Welding Fume extractors is rising day by day due to the increase in pollution. In India, Hytek Marketing is popular for providing the best welding fume extractor. We provide the best quality imported products that are productive, cost-effective, and durable.