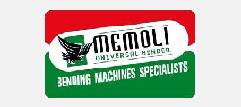

Plate Rolling Machines

Plate Rolling

What is a Plate Rolling machine?

It could be considered as a machine that is capable of rolling different kinds of sheet metal into round or conical shapes. They are also known by the name of “roll bending machine, plate bending machine or even roll machine”.

Plate rolling tool is used for what purpose?

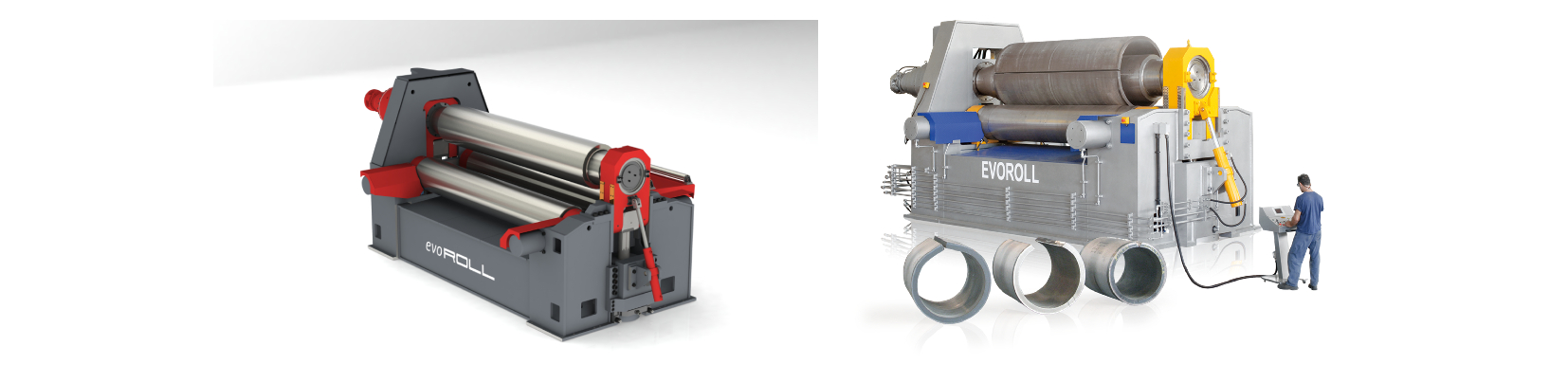

Plat rolling machines primary application is to shape a straight sheet into cylinder or similar shapes. They are capable of bending steel, both stainless and basic and they can also bend metals such as aluminum, copper, zinc etc.

These bend metals are then used for applications such as in construction, air conditioning, ventilation construction, roofing and industrial mass production.

With all these applications in mind, Hytek offers plate roller machines of 1960 Seravesi brand which is known for its reliability and quality across the globe. They also offer both manual and even very powerful hydraulic 4 roller plate rolling machines with NC and CNC controls.

Types of plate roller machines

- Four roll plate rollers

- Three roll plates rollers

- Variable geometry plate rollers

- Initial pinch plate rollers

- Slip roller

- Manual roll bender

1960 Seravesi®

1960 Seravesi relies on Tommaso Seravesi's knowhow (first in BSB, of the Seravesi brothers in 1960 and then in 1964 with the new company transformed into Sertom Srl being the initials of the surname and name of the founder SERavesi Tommaso), who has been the manufacturer of plate rolls, sheet metal roll machines, hydraulic presses, and flanging machines for over 50 years, besides supervising the building stage of the machinery and from strength, abilities, and professionalism of the team of specialists in the mechanical processing and assembly sector.

1960 Seravesi, Italy are manufacturers of:

• 3 Rolls With Variable Geometry Plate Rolling Machines With Double Pre-Bending;

• 4 Rolls Pyramidal Plate Rolling Machines With Double Pre-Bend;

• Vertical Tank Production System with Plate Rolling, Automatic Cutting, and Automatic Welding Station

• 6 Meters Pipes Production System with Plate Rolling, Post-Bending, Plates Loading, and Unloading

• Dishing Hydraulic Press With Automatic Manipulator;

• Straightening Hydraulic Press;

• Shipyard Hydraulic Press With Traveling Piston;

• Hydraulic Flanging Machines;

The E79's Key Features

BENDING of medium and large thicknesses (recommended from 25 mm to 300mm). It is the ideal machine due to its particular design because it has reduced sizes and a shorter straight section compared to the four rolls, and thanks to the tilt of all three rolls, there is the possibility to perform even complex conical processes, in a much easier way than with four rolls.

The PRE-BENDING obtained is excellent thanks to the high push of the top roll which is used in this phase as a bending press.

- REVOLUTION of its geometry: In fact, the bottom rolls move horizontally and are independent of one another with variable pitch, whilst the motorized top roll moves vertically.

- VERSATILE: increasing the distance between the bottom rolls very thick plates can be bent, whilst decreasing the distance it is possible to bend thin plates and so create tubes with a small diameter. Having a roll plate bending machine with variable axes is like having two machines in one.

- INDEPENDENT: the movement of the three rolls easily allows the creation of cones. The bottom rolls and top roll can tilt independently up to 2°.

- SAFE: for the safety of the operators, we made it possible, thanks to its particular geometry, that the plate stays in a horizontal position during every work phase. Furthermore, the machine is set up with an emergency stop push button to immediately stop its movement.

- SIMPLE to use and maintain thanks to easy accessibility of the hydraulic parts and the diagnostics on the control panel, that is always within reach of the operator.

- DIMENSIONS are small and compact in comparison to other bending machines that do not require the foundation pit up to a certain size.

Advantages

- Precise

- Productive

- Versatile

- Faster

- Reliable

- safer and easier to operate

Applications

- Boilers

.jpg)

.jpg)

.jpg)