Pipe Notching Machines

What are pipe notching machines?

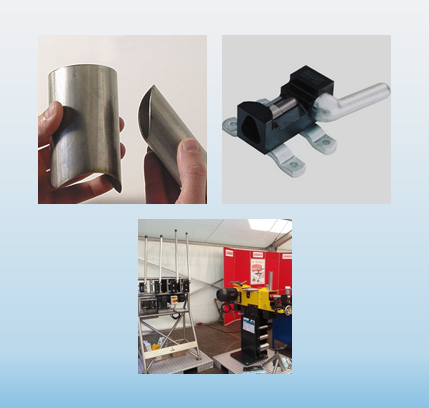

The Pipe notching machines or notching tools also called "abrasive notcher" or "tube notcher" are machines that work by abrasive belts. Pipe notching machines are designed to prepare tube corner joints for the welding process.

What is notching?

The notching is a specific processing performed on pipes and tubular square or rectangular sections in any metallic material, generally iron and steel.

Pipe notching equipment used for?

Pipe notching machines are used to notch/grind pipe tube ends to prepare the end for welding.

Features of pipe notching tool

- Fast, solid, stable, and accurate.

- Extremely suitable for quickly sharpening stainless steel.

- Do not cause grinding burrs and discoloration.

- Have grinding rollers that can be changed quickly without tools.

- Have a sanding belt that can be replaced quickly.

- Equipped with a handy grinding table.

- Suitable for both left-handed and right-handed operations.

- Suitable for grinding out any desired material.

- Grind any desired diameter at any desired angle between 30-90º.

- Guarantee of success and therefore have a three-year warranty.

- Thousands of satisfied users have already experienced it, ALMI machines are an investment that earns you money.

What is the Application of pipe notching machines?

- Furniture (Beds, Hospital equipment, Wheelchairs).

- Automotive (Exhaust, Seat frames, Stabilizers).

- Gymnasium Equipments-Baby Strollers.

- Material handling equipment.

- Stores display equipment.

- Cycle, motorcycle frames.

- Electrical appliances.

- Irrigation systems.

The benefits of pipe notching machines are as follows:

- Dry Cutting, no cutting oil required.

- High Productivity.

- Easy to operate.

- Guaranteed repeatability of angle.

- Proper profile matching with another tube results in reduced welding time & reduced welding wire usage.

- Better quality of welding process.

- Tool life is much longer as compared to a hollow mill cutter.

Learn how Pipe Notching Machines are important for your business

Why ALMI pipe grinders?

Processing stainless steel profiles and tubes at high speeds is quick and easy. And that without grinding burrs and tinting. Changing grinding rollers can be done quickly. No tools are required for this. Since this operation is repeated several times a day, you save a lot of valuable working time! Replacing the sanding belt is also easy and can be done on one side of the machine. After grinding profiles and tubes, they can be deburred on the handy deburring table at the top of the machine. The ALMI lever-operated machines are suitable for both left-handed and right-handed workers. With a simple operation, the lever can be placed on the right or left.

In short, ALMI pipe notchers offer you added value by guaranteeing years of trouble-free, accurate, and fast pipe processing. The guarantee of no less than three years serves as proof.

ALMI

ALMI strives for efficient and high-quality production. For example, ALMI is constantly updating the automation of the production process so that high quality remains the standard. Moreover, process control is guaranteed by the ISO 9001: 2008 certification. The recent NEN-EN-ISO 3834-2 certification serves as quality assurance for the welding process.

ALMI started robot welding at the end of the seventies. This experience led - in 2008 - to building the first robotic welding cell. This concerns a handling robot and welding robots. Hytek Marketing provides the best ALMI pipe notching machines for the best performance in the business in the most effective and efficient manner.