Welding Positioners

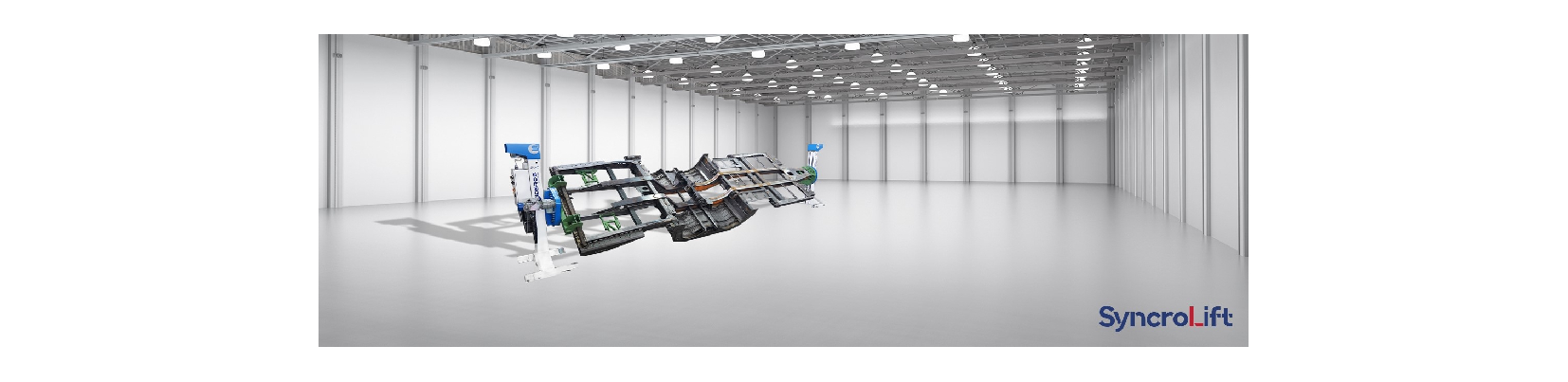

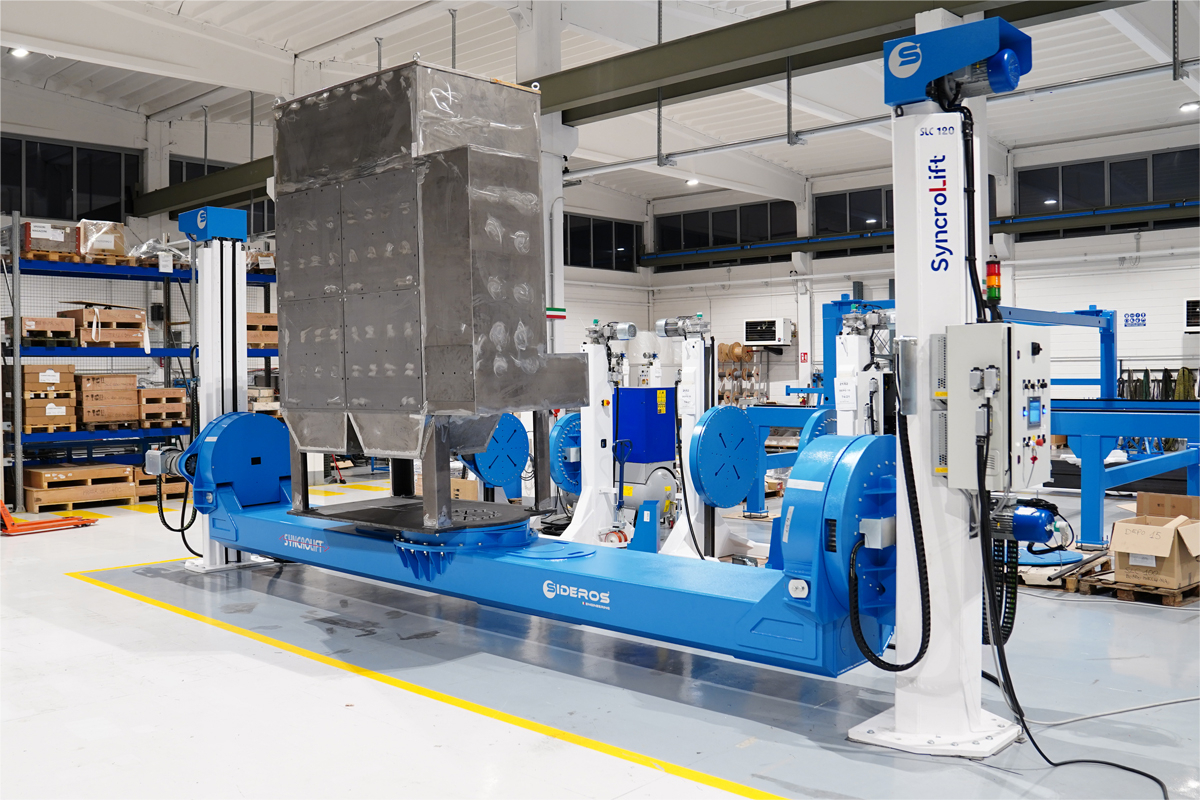

Head and Tailstock Positioners

Sideros Engineering Head & Tailstock Positioners are used to weld and assembly long and large weldments in many different application fields. Besides the benefits of ergonomics and safety during welding and assembly applications, the revolutionary feature of Syncrolift is the compactness and the portability of both columns, thanks to their dedicated hydraulic jacks. The result is an extreme flexibility in the factory. Syncrolift features two main axis: Electrical elevation/descent, and Electrical 360° left/right rotation. Syncrolift is configured with a fixed to the ground motorized headstock and an idler tailstock to adjust the workpiece length.

Advantages:

- Improved Safety

- Proper Ergonomics

- Improved weld quality

- Welding/Assembly procedures repeatability

- No need of particular maintenance even with continuous and heavy use

- Cost reduction and profit improvement

Railway Lifting Jacks

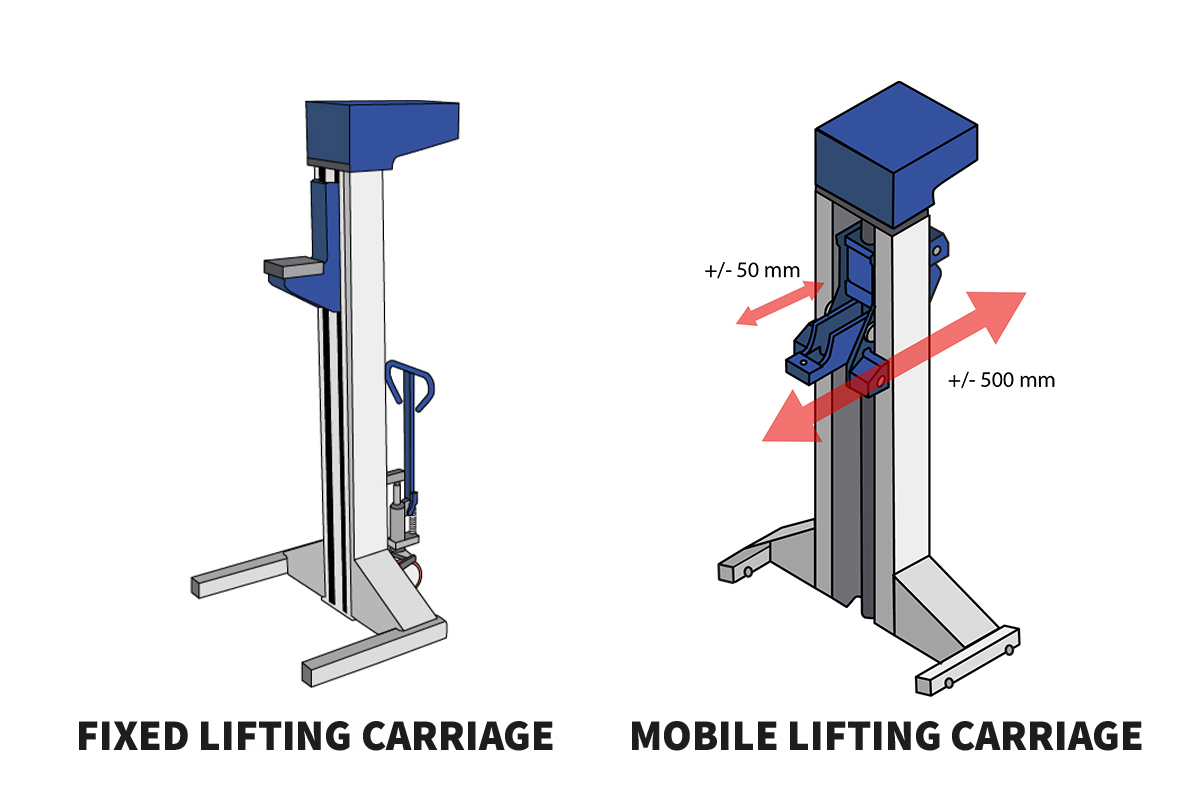

Liftmaster is a fully electric columns lift system, designed for raising rail vehicles, during assembly and maintenance operations. The system performs synchronized lifting and lowering of wagons, locomotives, boogies and complete trains.

The vehicles are placed on lifting carriages located on each column, to be subsequently raised. The lifting and lowering speed can be fixed or variable through VFD Inverter. The columns control panel is centralized on a single pulpit. Each column can also have its own independent movement for maintenance or adjustment operations. All columns have been optimized to be easily moved; in fact, with its hydraulic jack system and front/lateral wheels, the columns can be moved within the maintenance or production department with total flexibility.

Upon request, each column can be placed on special sliding tracks to allow proper positioning. The technical features of the lifts can be customized depending on the version and in particular on the Customer’s needs.

Skyhook Positioners

The Syncrolift Skyhook positioner represents the newest product developed in Sideros: it’s an evolution of the standard head and tailstock positioners. It performs an optimum ergonomics for welding and assembly processes, thanks to the possibility of turning the working piece by 180°.

The positioner is composed by a fixed column and a rotating arm, performing 3 main movements: upward/downward movements, turning over and rotation by 360°.

The L-Type positioner can also be easily customized in height, length of the arm and in load capacity up to 10.000 kg

Cradle Positioners

The Cradle Type SYNCROLIFT Positioner (2 fixed columns and a turning cradle) is equipped with a main cradle and a motorized rotary plate on which is loaded the piece. Even in this case, the positioner performs 4 main movements: upward/downward movement, turning over and rotation by 360°. Finally, the cradle type SYNCROLIFTS can also be customized in height, length of the cradle and in load capacity up to 20.000 kg.

.jpg)

.jpg)

.jpg)