Sheet Deburring Machines

What is deburring?

Deburring is the process of removing the small imperfections known as burrs from machined metal products.

What is deburring in sheet metal?

Deburring edges are essential in modern sheet metal processing in order to produce reliable and high-quality parts.

What does a deburring machine do?

A typical deburring machine contains one or more tools for smoothing burrs out of the machined metal. The orientation of the tools allows for consistent, quality deburring. Many deburring machines use a brush, disc, or belt heads for grinding burrs out of workpieces.

What are the different types of deburring?

Manual deburring: Manual deburring is the most common and economical deburring method.

Mechanical deburring: Mechanical deburring uses a deburring machine to grind the burr off. This method is costlier but much more efficient than manual deburring, so it is a popular option in machining operations.

Thermal deburring: Thermal deburring uses combustion gasses to generate thermal energy and essentially scald the burrs out of the metal.

Electrochemical deburring: Electrochemical deburring uses a solution of salt or glycol to conduct energy through the burrs. The electrochemical energy blasts away the burrs while leaving the surrounding metal intact.

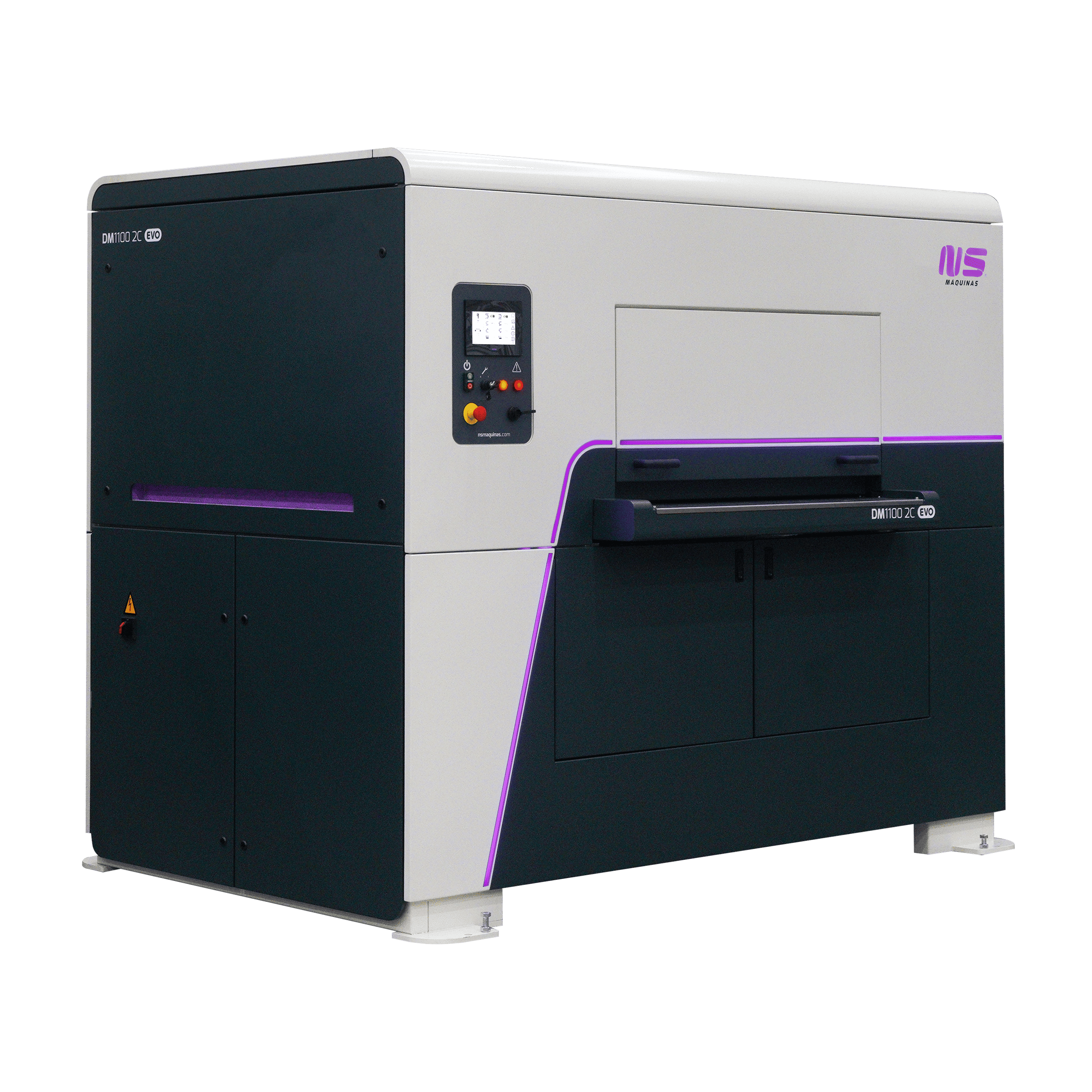

NS Máquinas is a manufacturer of machines for the metal finishing, deburring, and polishing industry. Located in Portugal, NS Máquinas is able to create and offer machines that combine quality and adequacy for diverse production requirements.

How does the Sheet metal deburring machine work?

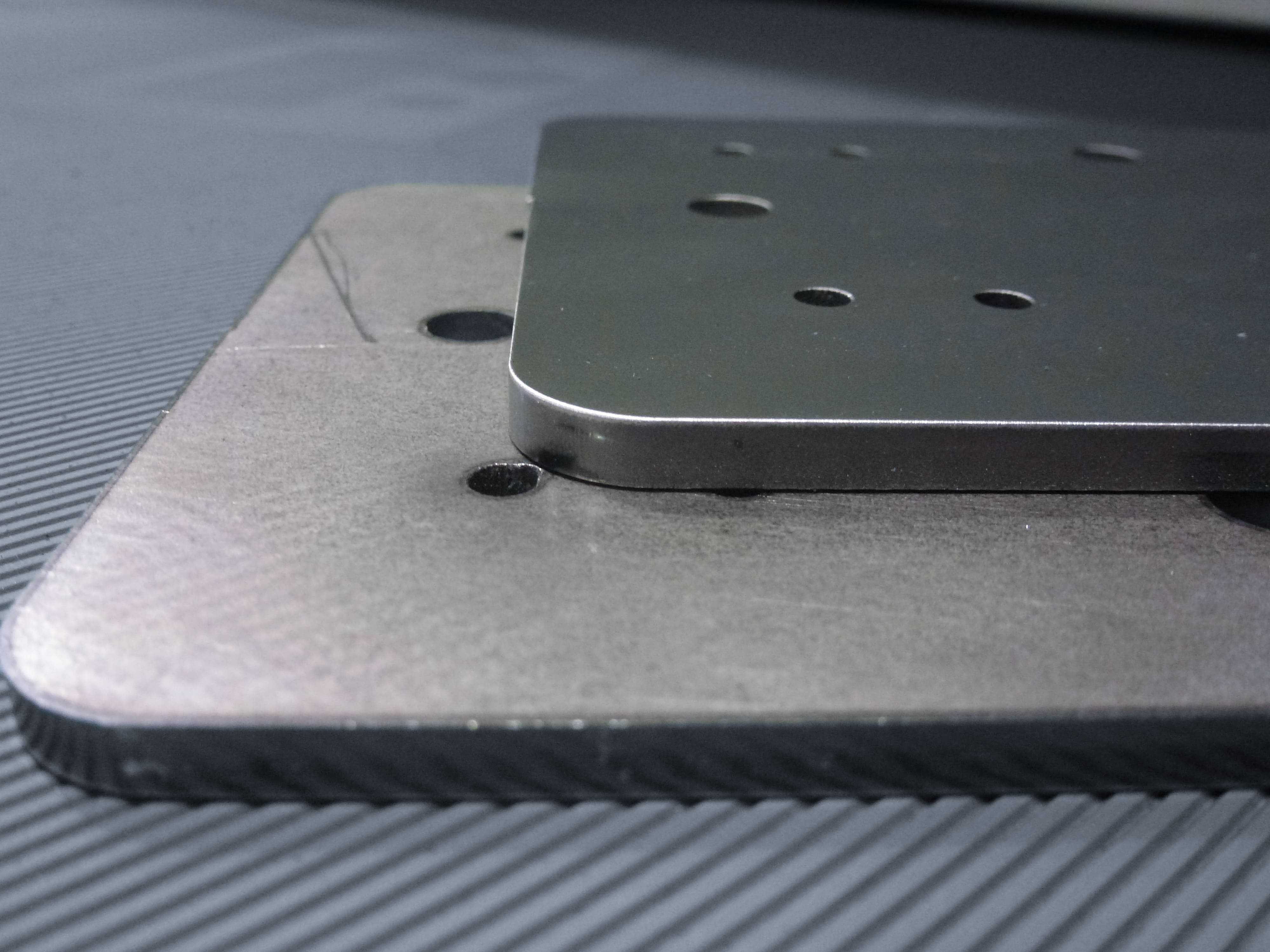

The sheet metal deburring machine and edge rounding machines from NS perform deburring as well as edge rounding and remove sharp edges on both external and internal contours of stainless steel, steel, or aluminum parts either cut in laser, shear, or punching machine.

The belt finishing or polishing machine has a station with double cross belts for the metal deburring and edge rounding, leaving clean, soft, and burr-free edges on the complete parts. The sheet metal deburring machine technology involves a contact roller combined with two cross belts mounted with abrasive blocks running in opposite directions, completing edge rounding on the complete area of the part.

There are various models of sheet metal deburring machines and other types offered by NS are following, that offer a lot of benefits to the end-user.

- Stainless steel deburring machine

- Steel deburring machine

- Aluminum deburring machine

- Automatic sheet metal deburring machine

- Edge deburring machine

- Sheet metal edge deburring machine

Why Is Deburring Necessary?

- Cracks and material failures

- Increased localized stress

- Decreased fracture resistance

- Failure after fewer stress cycles

- Poor fastener seating

- Fastener damage

- Increased susceptibility to corrosion

- Increased risk of static discharge

- Undesirable friction and heat

- Increased surface-to-surface wear

- Lubrication issues

- Overall diminished safety

Merits of the sheet deburring tool?

- Increase Efficiency. In metal fabrication, time is money

- Saves Money

- Higher Quality

- More Flexibility & User-Friendliness

- Safer

Applications of sheet deburring equipment?

- For The Military.

- Full Equipment Range.

- For the Aerospace Industry.

- For Automotive IndustryDeburring machines reliably remove any burrs left on the parts.

Hytek Marketing has always been able to acquire products of the highest quality and demand to meet the requirements of our clientele. Our partnership with Sheet Deburring Machines giants such as NS Maquinas could be of great benefit to our clients. If you would like to enquire about the range of products from NS Maquinas, contact us at hytek@hytekmarketing.biz or give us a call at +912040036057/229/48600290, we’ll be more than happy to assist you.