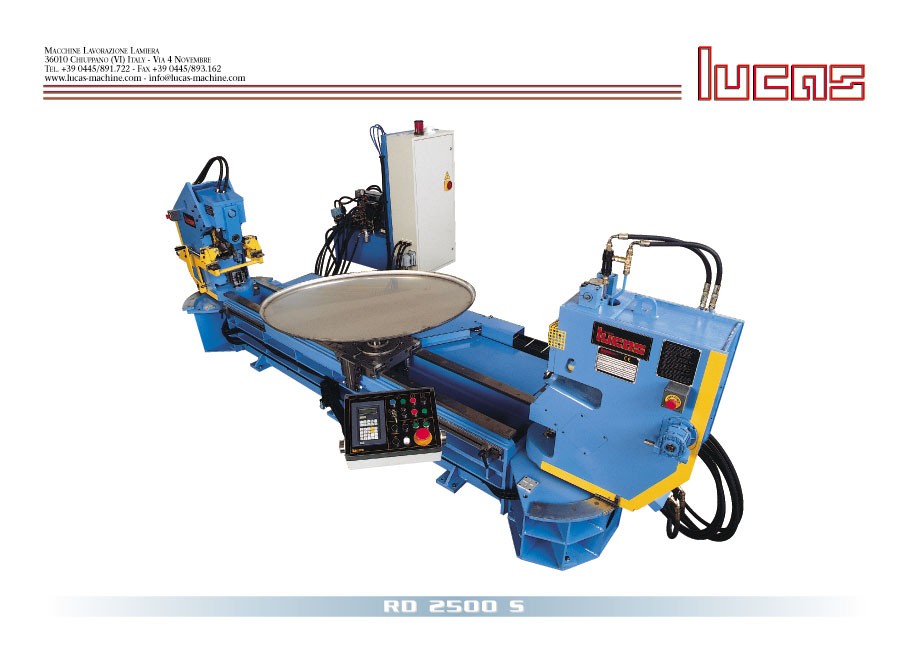

Shear Beading Machine

Lucas is a synonym for experience and know-how of the highest level, for the ability to foresee and interpret the market, for a complete and flexible range of solutions. In over 50 years in the business of supplying machinery for processing sheet metal the company has earned a leading position on the world markets, uniting family traditions and an efficient evolved workforce. Lucas production includes a wide range of trimming machines, beading machines, flanging machines, tube punching machines, circular shears and beading machines, in addition to special machines entirely designed upon specific request by the customer. Lucas products are the result of careful researches to help customers to develop new systems in the field of production and finished product, in small, medium and large-sized industry.

Thanking a quick set-up, the machine is suitable for high or low level production.

The production rate is 5 pieces per minute.

It’s a very compaction machine, composed by a circular shear with integrated transfer system, vacuum lifting device and pneumatic system for the scrap material extraction.

The standard machine can be supplied in the version 3 or 5 mm maximum thickness for cutting discs from 200 up to 1060 mm diameter (starting from square sheets).

Main construction characteristics:

- plate turn-over system by corner lifting and brushes;

- thickness and double plate checking system;

- cutting diameter visualization by display;

- set-up of the number of pieces to produce;

- plate centring system (by this system it’s possible

- visualization of the centering device position;

- scrap material extraction’s checking system;

- automatic unloading of the scrap material;

- automatic unloading of the cut disc and pallettization

- complete diagnostic system;

- alarm/checking system once finished the pieces to produce;

- safety protection.

You can also choose if you want to punch the central hole (optional)