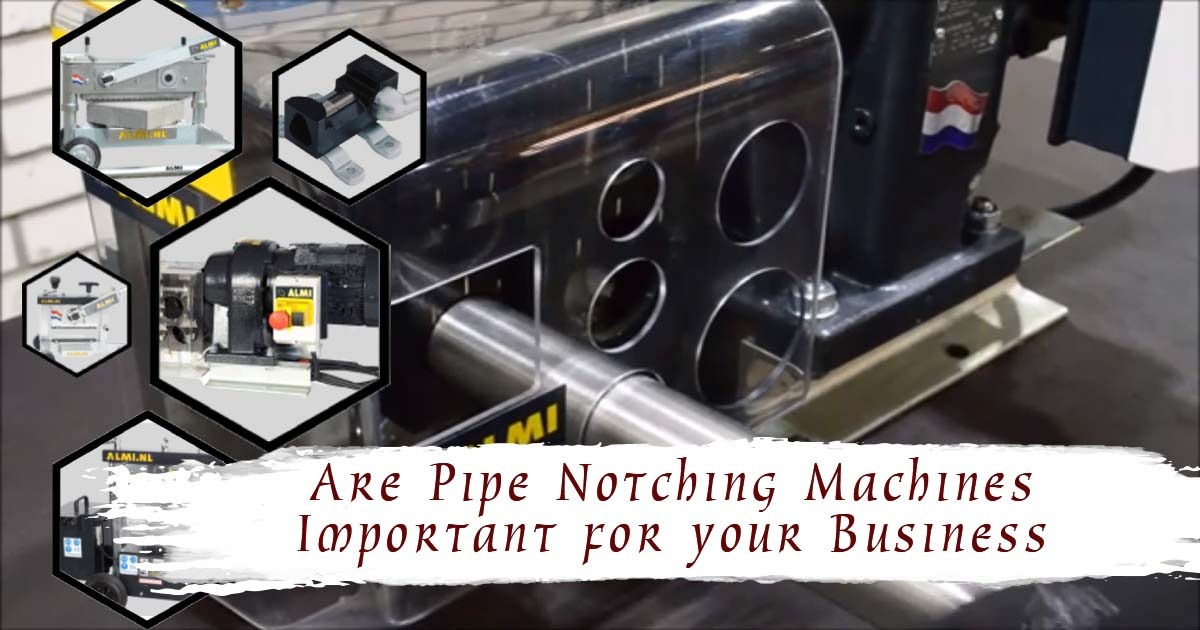

Are Pipe Notching Machines Important For Your Business

The Pipe Notching Machine tools are also called “tube notchers" which are machinery tools that work by abrasive belts. Pipe notching machines are formulated to prepare tube corner joints for the welding process. Notching is a specific process performed on pipes and tubular square or rectangular sections in any metallic material, generally iron and steel. The processing is performed by the abrasive belt mounted on the contact roller that plays as a matrix and determines the diameter of notching. The belt grinding notches are indicated for the construction of handrails, railings, bicycle frames, motorcycle frames and go-kart frames, structures, plumbing pipes, etc.

-

Pipe notching machines are used to notch or grind pipe tube ends to prepare the end for welding.

-

The notching angle is adjustable from 90 ° to the most inclined by 30 °.

-

The notch capacity is tube diameter/side minimum 20 mm in diameter/side maximum 245 mm.

Pipe notching machines are used to notch or grind pipe or tube end and longitudinal grooving to prepare the corners joint for welding. The belt grinder arm is hinged to the base, rotating it, the machine can work in two positions: - vertical tape: used to notch/grind pipe or pipe on longitudinal grooving. - vertical tape: used to notch/grind pipe or tube end. The notch capacity is tube diameter/side minimum 20 mm in diameter/side maximum 145 mm.

Unique Features of Pipe Notching Machine

Some of the salient features of Pipe Notching Machine includes:

-

Easy to operate

-

No cutting oil required

-

Corrosion resistance

-

Accurate angle cut guaranteed

-

The machine life is much longer with less maintenance cost as they are professionally designed with user convenience at heart.

-

They are of high quality with a proper profile that matches with different tubes with ease and this resulted in a reduction in time wastage as well as wastage.

Applications of the Pipe Notching Machine

They are applied in the following areas:

-

Coping round tubes or pipes together handrails

-

Furniture industries, gates, electrical appliances, stores display equipment

-

Gymnasium equipment baby strollers, hospital equipment, and chemical plants – petrochemical plants.

Use of Notching Machines in Mass Production of Tubular Structures

The notching machines are widely used in the bike frames fabrication process, tables with tube stand, building construction, automotive (seat frames, stabilizers, exhaust), cycle, motorcycle frames, irrigation systems, boilers tubes, material handling equipment, and refrigeration pipes. Furthermore, information about tube pipe notches using Pipe Notching Machine.

Get a quality Corner Notching Machine now..!

Conclusion

The notching machines are widely appreciated for exceptional efficiency, longer service life, easy to operate, cost-effective, less maintenance cost, proper profile matching with different tubes and notches, quality, and durable in functionality. There are various types of quality standard notching machines available in the market such as pipe and tube notching machines, Hydraulic notching machines, and Standard notching machines among many others. Its application includes furniture such as beds, building constructions, electrical appliances, store display equipment, gymnasium equipment baby strollers, and hospital equipment among many others.