Circular Saw

ILERI TEKNIK was established in Bursa in 1984 to produce machinery and spare parts. Since 1989, it has started to research the subject of circular saw machines and started production as a result of preliminary studies and designs.

The production, which started with manual and semi-automatic machines in the first years, continued with the development of fully automatic machines and automatic loading systems in the following years.

It started to make its first export in 1998 by working on foreign target markets. Today, ADVANCED TECHNICAL machines are operating in approximately 30 countries in 5 continents, especially in European countries.

Thanks to its continuous improvement and ability to develop new products, it has become one of the best known companies in its field and a valuable brand in the world today. ILERI TEKNIK claims to be the leading company in its field with its new products and projects for the coming years, quality machinery production, after-sales services and unconditional customer satisfaction.

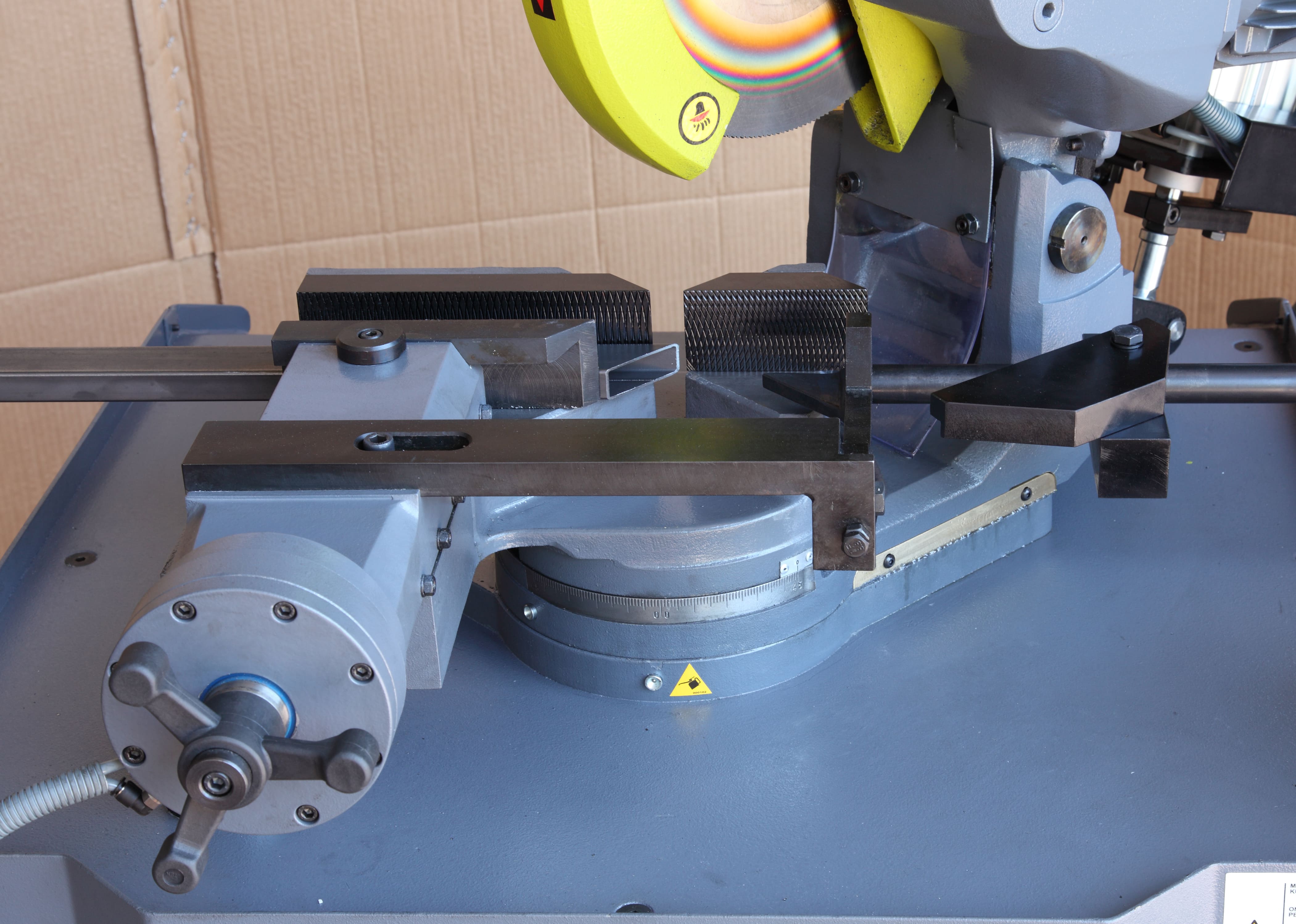

Manual Machines

It is the type of machine in which material squeezing and cutting is done manually. It is generally preferred in applications where different materials are cut continuously.

Vise Automatic Machines

It is the type of machine in which the material cutting process is done manually and the material clamping system is done automatically. It is preferred in low-volume jobs where materials are cut frequently.

Semi-automatic Machines

Semi-automatic sawing machine makes material clamping and cutting automatically. It has adjustable and controllable cutting speed thanks to hydro-pneumatic saw head. With the ability to select the most suitable speed for material properties Precise angle cutting can be done up to 45° in both directions.

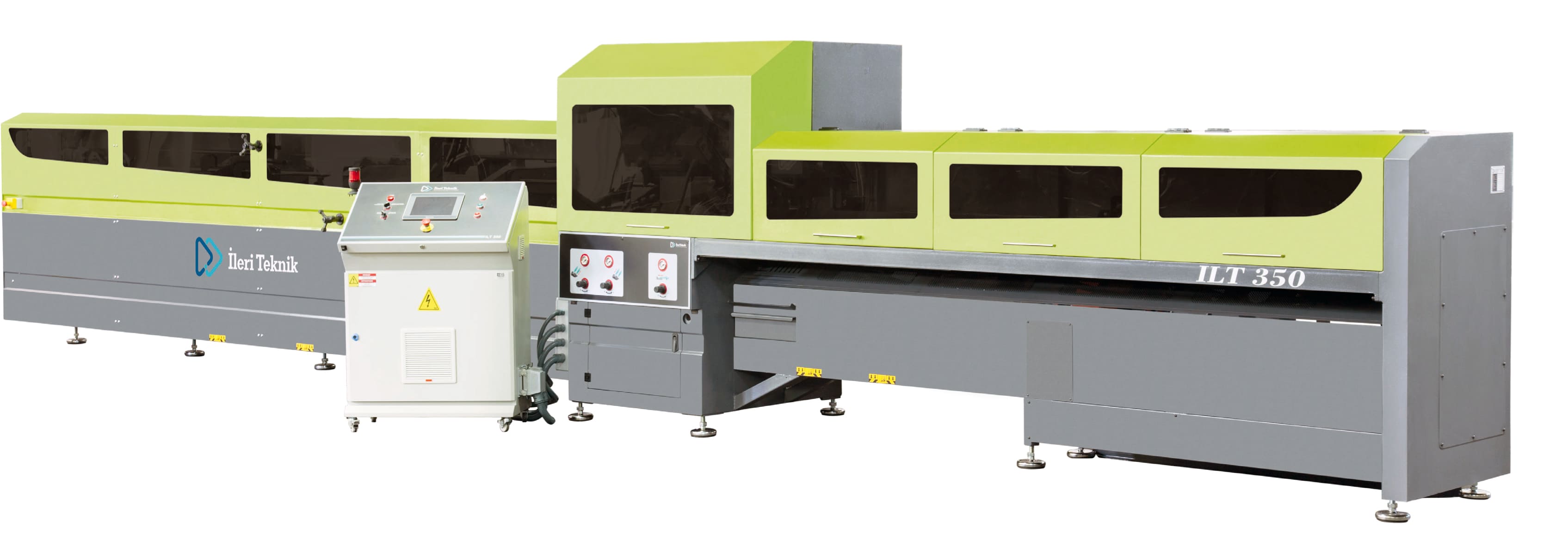

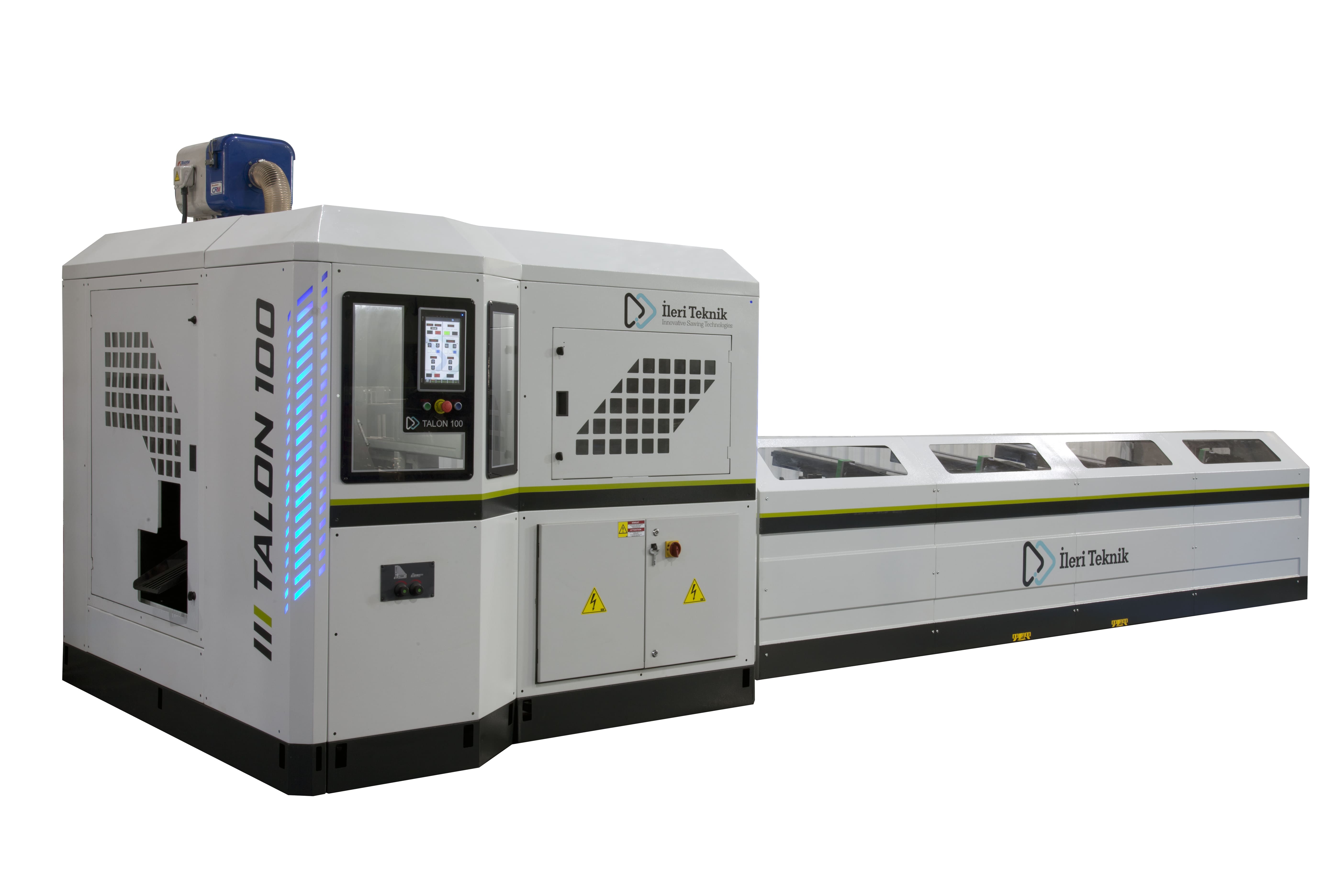

Fully Automatic Machines

-Material drive with servo motor and ball screw control

-Adjustable and controllable cutting speed thanks to the hydro-pneumatic working saw head

-Driving and cutting up to 1000 mm in one go

-Multiple slides over 1000 mm

-Opportunity to cut 4 different lengths on the same material

-Ability to select the most suitable speed according to material properties thanks to the double-speed motor

-High performance and double helical gear transmission reducer structure