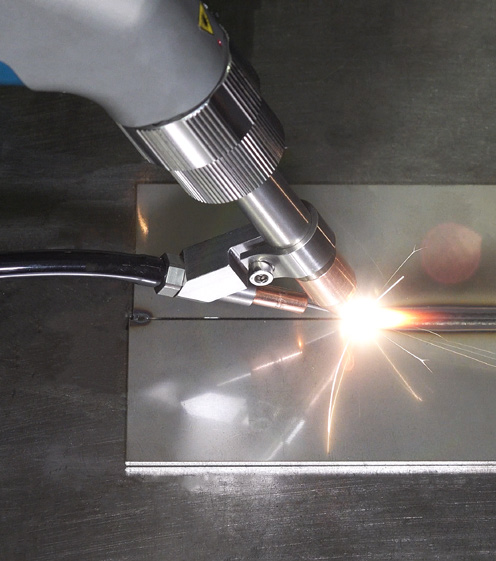

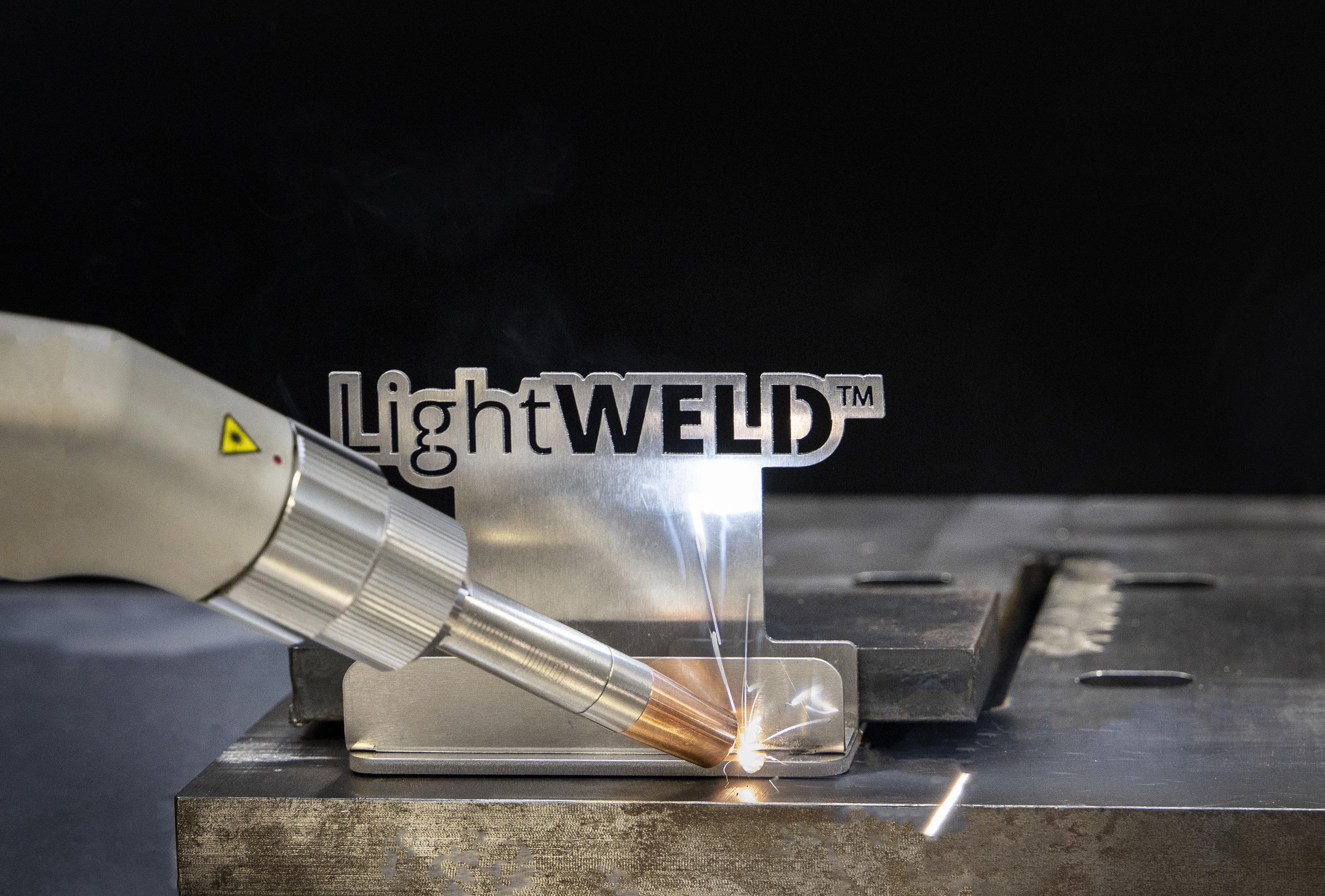

LightWELD Handheld Laser Welding Machine

IPG Photonics has a rich history of innovation, including the pioneering of technological breakthroughs that have helped transform how material processing, telecommunications and medical applications are implemented today by leading global organizations.

LightWELD - Laser Welding & Cleaning Systems

• Easy to Learn

• Built-in factory presets for welding and cleaning reduce learning curves, new welders can be trained within hour and experienced welders realize an immediate increase to productivity

• Highly Productive

• High-speed welding that is 4X faster than TIG, with simple material preparation and minimal post-finishing, plus wobble welding and wire feed options for consistent high-quality results

• Highly Capable

• Easily weld and clean thick, thin and reflective metals with low heat input from < .040" (1.0mm) up to 1/4" (6.35mm) with minimal part distortion, improved visual appearance and increased overall part quality

LightWELD - Turnkey Handheld Laser Welding & Cleaning Systems

• Adjustable laser welding power up to 1500 W

• Preset & user-defined modes optimize material-thickness combinations

• Wobble welding controls for 5 mm of additional weld width

• Rear panel provides intuitive connections for power, process gas and external accessory controls

• Cleaning power up to 2500 W peak for greater welding quality and finishing capability

LightWELD Unbeatable Benefits:

FAST: Up to 4X faster than TIG

VERSATILE: Wide range of materials – up to 1/4 in. (6.35 mm)

EASY: Optimized presets reduce learning curve

CONSISTENT: High-quality, repeatable results

FLEXIBLE: Simple and challenging applications

PRODUCTIVE: Pre- and post-weld cleaning capability

TIG welding is a time-consuming, two-handed welding method that requires an experienced, highly-skilled operator. TIG welding may generate extreme heat that deforms thin materials, produces poor visual finishes, is difficult when welding copper, and limited when welding metals of dissimilar thicknesses.

MIG welding requires consumable wire, material pre-cleaning and beveled joints for thick metals for full penetration. Travel and work angles are limited and vertical positions are extremely challenging.

LightWELD enables dramatically faster welding, is easier to learn and operate, and provides higher-quality, consistent results across a wider range of materials and thicknesses than MIG or TIG with minimal distortion, deformation, undercut or burn-through.

The low heat input and extensive material and thickness capabilities increase productivity, repeatability, and improve weld quality for operators of all skill levels. LightWELD welds dissimilar metals of different thicknesses with ease and creates aesthetic high-strength joints with minimal or no consumable wire. Plus, LightWELD XC and LightWELD XR offer built-in pre- and post-weld cleaning not found on any traditional system.

LightWELD is Fast & Easy to Set Up

• Ergonomic, compact and proven to be the most comfortable and easy to use laser gun with built-in wobble welding functionality.

• 2-step trigger and part contact sensor enhance operator safety

• Purpose-built nozzle tips for various weld joint types and pre and post weld cleaning applications

• Quickly switch from standard laser welding to wire welding, and from laser welding to laser cleaning

• A single cable from the unit delivers laser power, gas and control connections to the gun